Temperature‑Controlled Warehousing: Protecting Sensitive Goods from the East Coast to the Pacific Northwest

Many e‑commerce products—from probiotics and natural skincare to CBD edibles—require precise environmental conditions. This article explains the difference between temperature‑controlled and climate‑controlled warehouses and why they are essential for Amazon sellers.

What is temperature‑controlled warehousing?

Temperature‑controlled warehousing maintains specific temperature ranges to keep products stable. Unlike ambient warehouses (59–77 °F), which suit shelf‑stable items, temperature‑controlled facilities use advanced cooling, heating and monitoring systems to keep produce at 35 °F or frozen goods at –10 °F.

Climate‑controlled warehousing goes further by regulating humidity and air quality, protecting moisture‑sensitive items like fine wines or electronics. Sellers may need a mix of ambient, refrigerated and frozen storage depending on their product mix.

Why temperature control matters

For brands shipping sensitive products, proper temperature control is a strategic necessity. It preserves product integrity—probiotics can lose efficacy in hours at the wrong temperature, natural skincare oxidizes in heat and premium chocolate develops bloom. Correct storage extends shelf life, reduces inventory write‑offs and protects brand reputation. It also ensures compliance; agencies like the FDA and USDA require documented evidence that products stayed within specified temperature ranges. Positive customer experiences depend on receiving items in perfect condition; a melted or spoiled product can lead to negative reviews.

Cost control and waste reduction

Temperature breaches can be expensive. For a company shipping $1 million in temperature‑sensitive products annually, even a 5 % loss due to temperature compromise equates to $50,000 in direct losses. Modern monitoring technologies alert staff to potential issues before products are compromised, reducing waste and carbon emissions. Temperature‑controlled facilities also offer flexible space for seasonal spikes, ensuring sellers do not have to choose between meeting demand and maintaining quality.

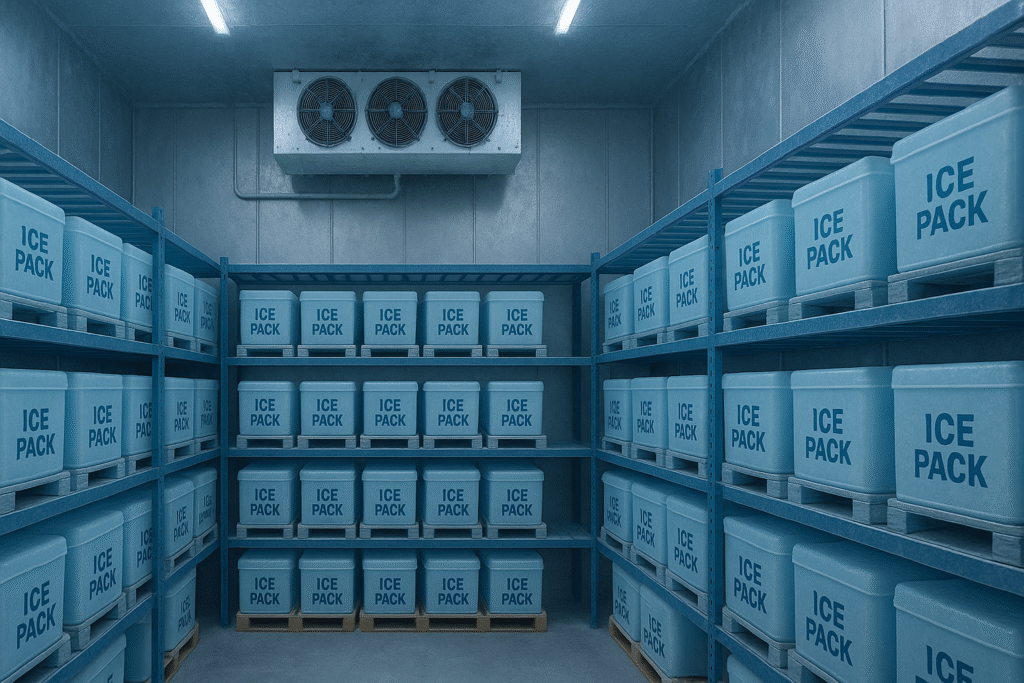

Types of temperature‑controlled storage

Ambient (59–77 °F/15–25 °C): Suitable for shelf‑stable products like canned goods and supplements, but still requires monitoring to prevent temperature spikes or drops. Geographic location influences ambient conditions; facilities in Phoenix may need supplemental cooling while those in Minneapolis may require heating.

Refrigerated (33–41 °F/1–5 °C): Ideal for fresh produce, dairy alternatives and temperature‑sensitive cosmetics. Maintaining consistent temperature and humidity requires significant infrastructure and air‑flow management.

Frozen (–0.4 °F to –13 °F/–18 °C to –25 °C): Used for frozen foods and certain vaccines. Frozen environments demand specialized equipment, worker protective gear and robust packaging to prevent thermal shock.

Specialized climate: Some products need precise humidity and air quality controls—e.g., fine chocolates, wines and sensitive electronics. Such facilities use sophisticated monitoring systems and are more expensive, but critical for premium products.

Selecting a 3PL for temperature‑controlled products

Certification and compliance: Look for warehouses with certifications such as GMP (Good Manufacturing Practices) or GSFI (Global Food Safety Initiative) to ensure regulatory compliance.

Monitoring and documentation: The provider should maintain logs and provide documentation showing products stayed within required ranges.

Geographic network: With warehouses in South Carolina and Oregon, our company can store refrigerated cosmetics for East‑coast customers and frozen goods for West‑coast buyers, reducing shipping time and risk of spoilage.

Conclusion

Temperature‑controlled warehousing is not merely “keeping things cold.” It requires precise environmental control, documentation and expertise. By leveraging a 3PL with climate‑controlled facilities on both coasts, Amazon sellers can protect product quality, satisfy customers and maintain compliance.